HELIUM MASS-SPECTROMETER

LEAK DETECTOR

MANUAL

(ENGLISH VERSION)

Contents

|

1 |

Safety requirements |

|

|

2 |

General information |

|

|

2.1 |

Function |

|

|

2.2 |

Technical specifications |

|

|

2.3 |

Parts list |

|

|

2.4 |

Operation principles |

|

|

2.5 |

Vacuum system of leak detector |

|

|

2.5.1 |

Mass-spectrometer analyzer |

|

|

2.5.2 |

Turbo-molecular pump |

|

|

2.5.3 |

Valves |

|

|

2.6 |

Construction of leak detector |

|

|

2.7 |

Scheme of electrical connections |

|

|

3 |

Leak detector оperation |

|

|

3.1 |

Operational restrictions |

|

|

3.2 |

Preparation for work |

|

|

3.3 |

Control panel |

|

|

3.4 |

Software |

|

|

3.5 |

Control of settings |

|

|

3.5.1 |

Settings menu |

|

|

3.5.2 |

Default settings |

|

|

3.6 |

Operating modes |

|

|

3.6.1 |

Automatic mode |

|

|

3.6.2 |

Operator’s work screen in automatic mode |

|

|

3.6.3 |

Manual mode |

|

|

3.6.4 |

Operator’s work screen in manual mode |

|

|

3.7 |

Archive screen |

|

|

3.8 |

Methods of leak detection |

|

|

4 |

Service and maintenance |

|

|

4.1 |

Cathode replacement and cleaning of mass-spectrometer analyzer |

|

|

4.2 |

Analyzer magnetic system adjustment |

|

|

4.3 |

Manual adjustment of accelerating voltage |

|

|

4.4 |

Vacuum system maintenance |

|

|

4.5 |

Cleaning of vacuum system |

|

|

5 |

Current repair |

|

|

6 |

Marking and sealing |

|

|

7 |

Storage |

|

|

8 |

Transportation |

|

|

Appendix A – Analogues of vacuum oils table |

|

|

|

Appendix B – Description of accessories |

|

|

DEAR CUSTOMER!

The leak detector TI1-50 is a modern highly automated device which allows to achieve the results of the world's best mass-spectrometer helium leak detectors.

Whereas leak detector has an easy-to-use interface, it is technically complex product. Before starting work it is necessary to read carefully this manual.

As the mаnufacturer makes permanent improvements aimed at the leak detector safety and quality level as well as its operational reliability increase, some insignificant changes which don’t influence the technical specifications and are not covered in this manual can be made in the product’s design and software.

Leak detectors TI1-50 are available in two versions, which are presented in Table 1.

Table 1

|

Item, type |

Designation |

TMP Type |

|

Leak detector ТИ1-50 |

ТФИЯ.406239.024 |

Edwards EXT75DX ISO63 |

|

Leak detector ТИ1-50-01 |

ТФИЯ.406239.024-01 |

TMHN-50/63 |

The leak detector of TI1-50 series complies with technical conditions 4215-023-07517692-2010.

This manual is intended to represent the operation principles and technical specifications of mass-spectrometer leak detectors of TI1-50 series (hereinafter referred to as ‘leak detectors’). It also contains the description of the device, it’s operation principles, technical specifications, and information required for proper installation, setting, checking, operation, maintenance, repair, storage and transportation.

Overall dimensions and appearance of leak detector basic configuration (with an inner forepump) are shown in Figure 1.

Figure 1 - Appearance and overall dimensions of leak detector basic configuration.

By agreement with the consumer, leak detector can be equipped with external forepump mounted on the transportation trolley. The appearance and overall dimensions are shown in Appendix ‘B’.

1 Safety requirements

1.1 According to the electrical safety requirements the leak detector meets the Class I requirements of protection, according to Russian national standard GOST 12.2.007.0-75.

1.2 The leak detector operation must comply with current rules of the electrical facilities use.

1.3 Leak detector is powered by an AC voltage of 220 V at 50 Hz with a protective earthing connection.

1.4 Preparation of the leak detector to work, carrying out maintenance, repair and replacement of vacuum system components must be realized when the leak detector is turned off only.

1.5 Operation of leak detector with removed covers is prohibited.

The employees carrying out the maintenance of leak detector must be instructed and have a right to work with electrical facilities up to 1000 V. Connecting of leak detector to the power supply and its disconnecting should be carried out strictly in accordance with the procedure described in this manual.

2 General information.

2.1 Function.

Mass-spectrometer leak detector serves to test the leaktightness of various systems and facilities which allow pumping the inner cavity or objects filled with helium or a gas mixture containing helium, and the detection and localisation of leakage sites (leaks).

The leak detector is a universal automatic device allowing the pre-pumping as well as operation in mode of ‘direct flow’ or ‘counterflow’, with an automatic choice of optimal mode by the control system in accordance with the characteristics of the tested object.

The leak detector is an indicator device. The error of determining the leak value is not standardized. Leak detector is not subject to verification.

The main application fields:

- leak detection of all types of vacuum systems and vacuum-objects in the process of their production and operation;

- leak detection of electron discharge and semiconductor devices;

- leak detection of various sealed and not able to be pumped objects, items.

Operating conditions:

- ambient temperature from plus 10 to plus 35 ° C;

- relative humidity up to 80% at a temperature of 25 ° C;

- atmospheric pressure is 86 - 106.7 kPa (630 - 800 mmHg).

2.2 Technical specifications

Technical specifications of leak detectors are shown in Table 2.

Table 2

|

Technical specifications |

TI1-50 |

TI1-50-01 |

|

Minimum detectable flow, m³·Pa/s: |

5. 10 -13 |

5. 10 -13 |

|

Maximum working pressure at the inlet, Pa: |

20 |

20 |

|

Time needed to reach ready mode, no more than, min |

5 |

5 |

|

Detectable mass, a.m.u. *** |

4 |

4 |

|

Productivity of high-vacuum pump, l/s |

60 |

50 |

|

Productivity of forepump, m³/h**** |

3 |

3 |

|

The minimum response time to the tracer gas flow at the inlet point, s |

1 |

1 |

|

The standard response time to the tracer gas with probe (10 m length, s) |

10 |

10 |

|

Continuous operation time, hrs |

24 |

24 |

|

Overall dimensions (WхHхD), mm **** |

484х470х392 |

484х470х392 |

|

Demand, V∙А **** |

500 |

500 |

|

Supply voltage of AC |

220 V, 50 Hz |

220 V, 50 Hz |

|

Weight (no more than), kg**** |

38 |

38 |

Notes:

*The value of the minimum detected by the leak detector flow in the countercurrent mode with the calibration by internal leak is associated with the value of the lowest detectable flow in the mode of direct flow through the correction coefficient (installed by the manufacturer) and is not verified separately.

** The typical value for a normal helium proportion in the atmosphere for the workroom (no more than 5 ppm) is indicated.

*** Leak detectors are adjusted to register helium isotope 4He; on request, the devices able to register isotope 3He supply is also available.

**** Weight and overall dimensions are indicated for basic set.

2.3 Parts list

The parts of leak detector are listed in Table 3.

Table 3

|

Item, type |

Designation |

Quantity

|

Note |

|

1.1 Leak detector TI1-50 |

ТФИЯ.406239.024 |

1 |

Version – |

|

1.2 Leak detector TI1-50-01 |

ТФИЯ.406239.024-01 |

1 |

Version – |

|

Parts and accessories: |

|||

|

2.1 Screw |

ЕХ8.900.028-01 |

6 |

For analyzer |

|

2.2 Screw |

ЕХ8.900.109 |

2 |

For analyzer |

|

2.3 Insulating bushing |

ЕХ7.860.074 |

15 |

For analyzer’s chamber |

|

2.4 Insulating bushing |

ЕХ7.860.075 |

2 |

For analyzer’s chamber |

|

2.5 Nut |

ЕХ8.939.022 |

2 |

For analyzer |

|

2.6 Focusing diaphragm |

ЕХ7.324.003 |

1 |

For analyzer |

|

2.7 Cathode (packed in a jar) |

50 |

For analyzer |

|

|

2.8 Gasket |

ЕХ8.683.392 |

2 |

For analyzer |

|

2.9 Gasket |

ЕХ8.683.393 |

1 |

For analyzer |

|

2.10 Gasket |

ЕХ8.683.400 |

2 |

Sealing of the pressure indicator |

|

2.11 Sealing ring ISO KF25 |

|

5 |

|

|

2.12 Blower |

ЕХ4.467.003 |

1 |

|

|

2.13 Nozzle |

ЕХ6.451.005 |

1 |

|

|

2.14 Grid |

ТФИЯ.301151.035 |

1 |

|

|

2.15 Diaphragm |

ТФИЯ.712741.003 |

1 |

For extending the range of working pressure at the inlet |

|

2.16 Sealing ring 030-033-19-2-6 GOST 9833-73 |

|

1 |

|

|

2.17 Sealing ring 014-017-19-2-6 GOST 9833-73 |

|

1 |

For valve V7 ‘Vent’ |

|

2.18 Filter |

SMC AN103-KM6 |

1 |

Mounted on the inlet ‘Vent’ |

| 2.19 Pressure sensor ПМТ6-3М-1 |

ОТО.399.097 ТУ |

2 |

Supplied only if leak detector has indicators ПМТ6-3М-1 |

|

2.20 Power cable (5 meters) |

|

1 |

For connection to the power supply |

|

2.21 Set of Hex wrenches |

|

1 |

For service the leak detector maintenance |

|

Operational documentation: |

|||

|

3.1 Leak detector TI1-50. Manual. |

ТФИЯ.406239.024 РЭ |

1 |

|

|

3.2 Leak detector TI1-50. Log. |

ТФИЯ.406239.024 ФО |

1 |

|

|

3.3 Forepump operational documentation * |

|

1 |

The forepump type is specified in the logbook (р.6) |

|

3.4 Helium leak ‘Gelit I’. |

|

1 |

A certificate ТДМКО.339.022 ПС may be added |

* The forepump type is determined in the contract.

The shape and designation of spare parts of SPTA kit are shown in Figure 2.

Figure 2 - spare parts of SPTA kit

The list of accessories supplied optionally is given in Table 4.

Table 4

|

Item, type |

Designation |

Quantity |

Note |

|

Maintenance of vacuum system kit |

|||

|

Gasket |

ЕХ8.683.392 |

2 |

For the analyzer flanges |

|

Gasket |

ЕХ8.683.393 |

2 |

For connectors of the analyzer flange |

|

Sealing ring ISO KF25 |

|

8 |

|

|

Sealing ring ISO KF16 |

|

8 |

|

|

Sealing ring 030-033-19-2-6 |

|

1 |

|

|

Sealing ring 014-017-19-2-6 |

|

1 |

Valve’s seal V7 |

|

Sealing taper (copper) for valve XSA1-12S |

|

4 |

|

|

Valve seal puller XSA1-12S |

|

1 |

|

|

Additional accessories supplied under the contract |

|||

|

Transportation trolley |

ТФИЯ.304136.006 |

|

|

|

Forepump |

|

|

|

|

Probe L =2 m |

ТФИЯ.408861.006-05 |

|

|

|

Probe L =5 m |

ТФИЯ.408861.006-06 |

|

|

|

Probe L =10 m |

ТФИЯ.408861.006-07 |

|

|

|

Probe L = 20 m |

ТФИЯ.408861.006-08 |

|

|

|

Probe L =30 m |

ТФИЯ.408861.006-09 |

|

|

|

External control leak |

ТФИЯ.406229.004 |

|

|

|

Remote Control |

ТФИЯ.467841.016 |

|

|

|

Vacuum chamber |

ТФИЯ.307141.002 |

|

|

|

Software for the leak detector control from external PC |

|

|

Supplied on CD or flash-drive |

Note: depending on the characteristics of the tested items and on tests technology the leak detector can be optionally equipped with special accessories (forepumps and appliances mounted on the leak detector or tested items, etc.).

Types of vacuum oils allowed to use in rotary-vane pump are given in Appendix A.

The remote control and external control leaks are described in Appendix B.

2.4 Operation principles

Leak Detector is a highly sensitive magnetic mass-spectrometer set for registration of the flow of the tracer gas (helium).

Leak is determined by the helium flow penetrating into the tested volume during the vacuum test, or by the flow of helium going from the tested volume at a excessive pressure in it.

Leak detector consists of a vacuum system, keyboard and display with the central processor, analyzer power device, amplifier of pressure passages, valves control device, electrometric amplifier and power supply sources. The main element of the leak detector is the mass-spectrometer analyzer, consisting of the ion source, the magnetic system and the ions collector.

The mass-spectrometer analyzer enclosed in a nonmagnetic steel casing is placed between the poles of a permanent magnet.

Incandescent tungsten cathode of ion source emits electrons that are accelerated by the electric field applied between the cathode and the ionizer of the ion source body. The cathode electronic current is stabilized by the emission stabilizer.

In the ionizer, the electronic flow clashes with the gas molecules which enter the leak detector from tested volume or probe, causing their ionization. New ions are extracted from the ionizer chamber with accelerating electric field acting in a direction perpendicular to the electronic beam. This field size is determined by the accelerating voltage value able to vary to ensure the necessary ion beam energy. The ion flow enters, through the outlet diaphragm, the drift space where the ions are subdivided according to their masses.

Influenced by the constant magnetic field directed perpendicularly to the movement direction, ions follow circular trajectories radiuses of which depend on ions masses. The trajectory radius of ions movement, in centimeters, is determined by the formula:

, (1)

, (1)

where:

R – ion movement trajectory radius, cm;

H - magnetic field density, A/m;

U – potential difference accelerating ions, V;

M – efficient ion mass, equal to its mass/charge ratio.

In the magnetic field, the ionic beam leaving a source divides into the separate beams containing ions with the identical mass/charge ratio. The movement trajectory radius of ions of a certain mass can be varied by changing accelerating voltage at invariable density of a magnetic field. The leak detector is equipped with the analyzer with 180-degree beam turn range and magnetic focusing.

The trajectory of ions movement from the ions source toward the ions receiver is semi-circular. The radius of ions trajectory is approximately 2,5 cm at magnetic field force 0,17-0,25 T.

The magnetic field in space of drift has focusing property: the ions of a certain mass leaving the ions source as a divergent beam, meet again in the form of a convergent beam in the plane of an inlet diaphragm of the receiver. Change of accelerating voltage ensures adjustment for ‘helium peak’ at which helium ions are directed to the receiver of ions.

Ion collector is connected to the inlet of an electrometric amplifier. Its signal is transmitted to the DC (direct current) amplifier, and then, after the software processing, to the control and display unit.

For the analyzer and flows control adjustment, the built-in helium leak of ‘Gelit-1’ type is used.

Working pressure in the mass-spectrometer analyzer is provided by exhaust system consisting of a forepump and of high vacuum turbo-molecular pump.

2.5 Vacuum system of leak detector

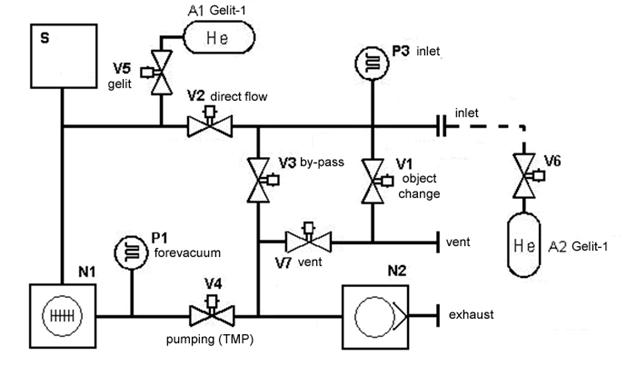

Schematic vacuum system of leak detector TI1-50 is shown in Figure 3.

S - mass-spectrometer analyzer

V7 – normally opened electromagnetic valve DN1,6

V1,V5,V6 – normally closed electromagnetic valve DN1,6

V2,V3,V4, – normally closed electromagnetic valve DN1,6

N1 – turbo-molecular pump, N2 - forepump

A1,А2 - helium leak ‘Gelit-1’. The elements V6, and A2 are included in external control leak, which is supplied on request.

P1, P3 – pressure sensors.

Figure 3 - schematic vacuum system of leak detector TI1-50

Evacuating of the tested object is realized by pumping system of leak detector consisting of a forepump (N2) and a high-vacuum turbo-molecular pump (N1). Pre-pumping of the tested object to the working pressure is realized through the valve (V3). The work of leak detector in the ‘counterflow’ mode is realized when the valves V3 and V4 are opened. The work of leak detector in the ‘direct flow’ mode is realized when the valves V2 and V4 are opened. Valve V1 is designed to vent a free air into the tested object when it is changed without stopping the leak detector. Valve V7 is designed to vent a free air when leak detector is turned off or if there is an emergency power failure. Valves V5 and V6 provide connection of control leaks.

Control of inlet pressure is provided by the indicator P3. Control of pressure of the forevacuum line is provided by the indicator P1.

2.5.1 Mass-spectrometer analyzer

The scheme of mass-spectrometer is shown in Figure 4.

The analyzer has a demountable design that provides the opportunity of periodic cleaning and washing. The camera body is a rectangular tube with two flanges. An electrode system is attached to the body flange, mounted on the flange, which has 3 screws for easy removal of the flange during maintenance and repair.

Figure 4 – Mass-spectrometer analyzer

Basic elements of the analyzer:

Leaktight connector of electrometric amplifier (1); gasket of leaktight connector (2); electricity cable of central diaphragm (3); leaktight connector of ions source (5); gasket of leaktight connector (4); electricity cable of cathodes K1, K2 (6); electricity cable of suppressor diaphragm (7); electricity cable of ionization chamber (8); ions collector (9); collector diaphragm (10); suppressor diaphragm (11); inlet diaphragm (12); outlet diaphragm (13); insulating bushings (14); cathode (15); intermediate diaphragm (16).

180-degree angle of the ions rotation in the analyzer and the necessary radius of the trajectory of ions is provided by the location of these elements on the single assembly base – angle bar, attached to the flange (17). The flange, (17) through the gasket, (19) is fixed in the analyzer body (18) with six screws M6.

The ions source consists of two cathodes, the ionization chamber, the outlet diaphragm (13). The cathode is a spiral of tungsten wire welded to the plates-electrodes. The power supply to the electrodes of the ions source and ions collector is realized through seven-pin sealed connector (5).

The analyzer is located in the interpolar gap of the magnetic system with permanent magnets, which provides the magnetic field strength in the range from 0.17 to 0.25 T. The design of the chamber does not require the removal of the magnetic system for maintenance of the analyzer.

2.5.2 Turbo-molecular pump

Turbo-molecular pump is a means of pumping, its operating principle is based on the difference of probabilities of gas molecules passage forward and backward through the slanted grooves of the rotor (turbine), rotating at high speed. In order to increase the degree of compression and expansion of the range of allowed inlet pressures of leak detector to greater values, the pump is additionally equipped with a viscous pumping stage (Holvek’s stage). The controller integrated into the turbo-molecular pump (for the model TI1-50) located next to the TMP near the side wall of the device (for the model TI1-50-01) controls the turbo-molecular pump operation. DC (direct current) provides the power supply of the controller. The controller is built in the leak detector control system and doesn’t require any additional settings.

2.5.3 The valves

In the leak detector, three types of electromagnetic valves, with a flow diameter DN 1.6 (normally opened and normally closed) and DN25, are used. Normally opened valve DN 1.6 (Figure 5) is used to vent air into the forevacuum line (to the pump inlet N2) when power is turned off. This operation is done automatically when the pump is disconnected. It is also necessary to prevent the oil overflow by the atmospheric pressure from the pump case into the vacuum system when it stops. Normally closed valves DN 1.6 (Figure 6) are used to vent an atmosphere on the inlet of leak detector in order to change the tested object, as well as for connection and disconnection of calibrated leaks during setup and calibration of device.

1- valve body, 2- rod of magnetic circuit, 3- valve anchor, 4- return spring, 5- solenoid, 6- gasket

Figure 5 - Normally opened valve DN 1.6

1- retaining ring, 2- solenoid, 3- magnetic circuit, 4- rod, 5- gasket, 6- return spring, 7- plate, 8- valve

Figure 6 – Normally closed valve DN 1.6

For the vacuum system switching at various operating modes electromagnetic valves DN25 (Figure 7) are used. The valves DN25 have two modes of operation: switching-on mode and hold mode. In the switching-on mode, there are 3.5 A current pulse and 200 V with a duration 15-20 ms (forcing) at the valve coil. After the valve switching-on operating DC voltage with a value of 24 V at 0.3 A is applied to the coil winding. This scheme decreases the overheating of the power coil winding, at keeping the valve opened for a long time in the process of operation. Valve operation unit is used for control of valves in leak detector by the commands of the leak detector operating system.

1- retaining ring, 2- solenoid, 3- gasket, 4- anchor, 5- valve body, 6- holder, 7- return spring, 8- sylphon, 9- gasket, 10- valve body

Figure 7 - Valve DN25

2.6 Construction of leak detector

The leak detector is mounted on the aluminium framework. The device rigidity is provided with application of T-shaped bars and welding of the framework elements. An access to elements of vacuum system and units of a control system is provided after removal of the covering panels.

The vacuum system is made from the standard elements connected by means of quick-split connection of ISO KF type. Connection of a high-vacuum part of the leak detector consisting of the analyzer and the turbo-molecular pump, is provided by means of bolt joints and rubber gaskets. The design allows to dismantle the vacuum system for a preventive maintenance without use of special tools and provides a high level of consolidation of the system elements. The arrangement of elements of the vacuum system and of its main units is shown in Figure 8-12 (the covering panels are removed)

1- electrometric amplifier, 2- pressure sensor Р3 passage, 3- sensor P3, 4-magnetic system polar tip, 5-transformer T1, 6-V5 valve (by-pass), 7- pressure sensor Р1 passage, 8-V7 valve, 9-forepump.

Figure 8. The leak detector front side arrangement.

1,15-quick-split connections DN25, 2- sylphon of the turbo-molecular pump; 3- fastening screws of the turbo-molecular pump, 4- magnetic system adjusting screw, 5- magnetic system fastening screw, 6- magnetic system fastening frame, 7- analyzer flange, 8- analyzer flange fastening screws, 9-connector of the analyzer power supply, 10-control leak ‘Gelit-11’, 11-tube of the vent line, 12-V1 valve (object change), 13-tube of the V7 valve, 14-V5 valve.

Figure 9. The leak detector back side arrangement.

1- inlet leak detector flange, 2- turbo-molecular pump, 3- controller of the turbo-molecular pump operation board (in version TI1-50 is not applied), 4- connector of the turbo-molecular pump cooling fan (in version TI1-50 is not applied), 5-V5 valve of the built-in control leak, 6-outlet flange of the turbo-molecular pump, 7- check screws of side panels fastening, 8- oil level of the forepump observation porthole (the other-side placement of the forepump is possible), 9-V2 valve of a direct flow switching.

Figure 10. The leak detector right side arrangement.

1- valve control, 2- adjusting screws of the magnetic system, 3- fastening screws of the magnetic system, 4- pole tips of the magnetic system, 5- analyzer power supply, 6- connection unit, 7- engines and valves control board.

Figure 11- The leak detector top side arrangement.

1- opto-relays of forepump control, 2- external forepump connection flange, 3-pulse supply source 12 V 25 W, 4- vent line tee (if external forepump is installed, under the contract, is not supplied), 5- pulse supply source of turbo-molecular pump 24 V 100 W, 6- supply-line filter, 7- pulse supply source 24 V 25 W, 8- ground bus, 9- connection block.

Figure 12- The leak detector bottom arrangement.

2.7 Scheme of electrical connections

Basic electrical circuits for leak detector TI1-50 are represented in Figures 13 and 14.

Figure 13- Electrical circuit of leak detector TI1-50 version

Figure 14- Electrical circuit of leak detector TI1-50-01 version

Figure 14- Electrical circuit of leak detector TI1-50-01 version

The electrical circuit of leak detector contains elements that are combined in the following units: power supply unit consisting of a socket, combined with fuse ‘F1’, the power switch ‘S1’ and supply-line filter ‘Z1’; unit of pulse power supply sources, consisting of source ‘A19’ - providing turbo-molecular pump power supply, source ‘A20’ - providing power supply of leak detector control system, as well as source ‘A21’ - providing analyzer power supply.

Transformer T1 - forms trigger valve voltage of vacuum system.

The coupling element ‘A2’ - is a cross-board of internal connection bus RS-485.

Analyzer power supply unit ‘A3’ provides formation of supply voltage of the analyzer. It is controlled from board A1 by internal bus RS-485.

The engines and valves control board ‘A4’ - provides formation of valves control commands DN1.6 that do not require forcing supply voltage: ‘V1’, ‘V5’, ‘V7’, ‘V6’, by the turbo-molecular pump ‘M2’, by the opto-relays ‘K1’ of the forepump ‘M3’ power supply control. It is controlled from board A1 by internal bus RS-485.

The valves control unit ‘A5’ - provides formation of valves DN25control commands that require high voltage forcing for the opening: ‘V2’, ‘V3’, ‘V4’. It is controlled from board A1 by internal bus RS-485.

Pressure passage transformer ‘A6’ - provides the power supply of pressure sensor ‘A16’ and converts its signal to a serial format RS-485 of the internal control bus.

Pressure passage transformer ‘A7’ - provides the power supply of pressure sensor ‘A17’ and converts its signal to a serial format RS-485 of the internal control bus.

Electrometric amplifier ‘A8’ - amplifies a ion current of the mass- spectrometer analyzer collector and its transforms into a serial format RS-485 of the internal control bus.

The control and display board ‘A1’ contains control and indicator units, memory module and the central processor of the system. This board controls all boards of leak detector by internal bus RS-485. The external control units are also connected to the board ‘A1’: ‘PC’ connector, for the leak detector external control (e.g. from a PC), ‘Remote Control’ designed to connect the remote control.

3. Leak detector operation

3.1. Operational restrictions

The sensitivity of leak detector and of leak detection control system (with a connected tested object, connection fittings, etc., to the leak detector) depends on the background concentration of helium in the atmosphere of the tests rooms and may be different. This dependence is especially evident when the leak detection methods associated with sampling from the environment (for example, the probe method) are used. Leak detector must be operated in a room that has no external helium sources which are not provided by the technological process or by the testing procedure method. Certificate leak detector sensitivity can be achieved only if the helium density in the atmosphere of the test room does not exceed the normal value for the open air, equal to 5 ppm (5 ∙ 10-4%).

Objects tested by the evacuation method should have a sufficient mechanical strength and to withstand an atmospheric pressure. Objects tested by high pressure test with helium should have a sufficient mechanical strength and withstand an excessive pressure of the tracer gas mixture.

Attention! To avoid bearings damage of the turbo-molecular pump because of the arising gyroscopic moment on the rapidly rotating rotor the leak detector transportation in the ON state is prohibited. During transportation of switched off leak detector equipped with a rotary-vane pump, the inclination of the device exceeding 30 degrees is not allowed. Leak detectors should be placed on a horizontal surface during operation.

Read this manual carefully before starting work and carry out preparatory works referred to in ‘Preparation for work’ section.

If the leak detector has been in a relative humidity exceeding allowable working values, it is necessary to keep it in normal conditions for at least 24 hours before switching it on. If the leak detector was at negative temperatures it is necessary to keep it under normal conditions for at least 8 hours.

The connection of the leak detector to the power supply 220V, 50Hz should be done only through the socket, equipped with a protective earth contact.

The rooms for leak detector testing and storage must be free of dust, chemically active substances and others harmful contaminants that can cause corrosion of components.

3.2 Preparation for work

Before the leak detector installation, make sure that there are no damages of the package. If the leak detector in a package was stored or transported at negative temperatures it is necessary to keep it in normal conditions for at least 8 hours. To avoid leak detector damaging during transportation, forepump is supplied separately in separate package.

Preparation for work of leak detector with an internal forepump (installed inside the device) is realized in the following order:

- unpack the leak detector and the pump, check the compliance of the package contents with the parts list (Table 3). Check the leak detector and the pump for damages.

- install the leak detector at the working place, providing easy access from all sides.

- remove the protective film from the screen surface without using sharp objects.

- remove the cap from the inlet flange of the leak detector.

- remove the top cover by removing four screws (two on each side), located in the hollows of side handles.

- - remove the right and left side panel by loosening eight set (check) screws, four of which are located at the corners of the frame under the top cover, two - on the bottom of the body at the front side and two on the bottom of the body at the back side of the leak detector (in the feet area). Loosening of the set screw allows to take out the side panels with the pins installed on them.

- remove the front panel by unscrewing the screws, located on its inner side.

- fill the pump with oil according to the instructions.

- mount the pump on the tray. Make sure that the pump moves freely on the dampers, without touching the frame.

- remove transportation ties fixing the position of the power cord and inlet sylphon and the pump exhaust hose, in the leak detector body.

- remove the clamp and the transportation cap from the sylphon of forepump. The clamp and the sealing ring are used for connection of the pump to the leak detector vacuum system.

- connect the power cord and outlet hose to the pump. The power switch on the pump body (if available) must be set to ‘I’ position.

- mount the front panels, then the side panels, avoiding any inclinations. Fasten the panel pins with check screws and mount the top cover.

- put the cap on the leak detector inlet.

Preparation of the leak detector for work with an external forepump is realized in the following order:

- unpack the leak detector, the trolley and the pump, check the compliance of the package contents with the parts list (Table 3). Check the leak detector and the pump for damages.

- mount the handle on the trolley and fasten it with the screws (included in the package).

- remove the transportation fastening elements and remove the tray from the trolley.

- mount the pump on the tray and remove the cap on the inlet flange of the pump.

- fill the pump with oil included in the pump delivery set (during the installation of oil forepump), according to the pump operation instructions.

- install the oil vapor trap on the pump exhaust (if the trap is included in the package contents) according to the trap label instructions.

- remove the top, side and front panels of the leak detector according to the instructions for the leak detector with an inner forepump.

- install the leak detector on the trolley and fix it with clamps (included in the trolley package contents).

- install the sylphon (included in the trolley package contents) with a gasket and a clamp on the flange connection of an external pump, passing the sylphon through the hole of the trolley top panel and the leak detector bottom.

- install the sylphon on the forepump flange with a gasket and a clamp.

- connect the pump power cable to the jack ‘Ext. FP’on the panel for external devices (Figure 15), passing it through a hole in the back of the trolley. The power switch on the pump body (if available) must be set to ‘I’ position.

- fix the earthing wire from the pump body to the grounding point situated below the hole for the pump power supply in the back of the trolley.

- mount the front, then the side panels, avoiding inclinations. Fasten the panel pins with check screws and mount the top cover.

- install a cap on the leak detector inlet or connect its inlet to the tested device.

1- circuit cable connection unit with fuse and power switch, 2- power cord jack of the external forepump, 3- nameplate, 4- jack of an external PC, 5- jack of the remote control, 6- jack of a cable of the external control leak, 7- jack of the of external valve power supply, 8 - connection port of the exhaust line. Can be connected to an external ventilation line with polymeric hose with an outer diameter of 8 mm, 9 - connection port of the purified gas line for the the forepump inlet vent, and for the tested object. If there is no purified gas source, install a filter included in the SPTA kit (§ 2.18).

Figure 15 - The appearance and the function of the panel for external devices connection.

3.3 Control panel

The control of leak detector is realized with a quasi touch-control switchboard, as well as rotating encoder handle in combination with a screen menu. To validate the input data press the encoder handle (ENTER function). One group of the keys with their LED indicators is located on the mimic panel figure in the left side of the front panel and is designed to control the vacuum system in manual mode (except for the button ![]() which allows to enable or disable the active cathode in the ready mode of leak detector, as well as buttons

which allows to enable or disable the active cathode in the ready mode of leak detector, as well as buttons ![]() and

and ![]() that allow to control valves of built-in and external leaks during the vacuum tests). Indicators provide a visualization of the state of the vacuum system in manual and automatic mode. The second group of keys and an encoder handle are located on the right side of the panel and are designed to control the most important and frequently used functions of the leak detector (start/stop tests, object change, background compensation).The keys start / stop, as well as background compensation have a light indication of the state. In case of pressing the locked buttons, the acoustic radiator (situated on the print board under the control panel) makes a sound to report an error.

that allow to control valves of built-in and external leaks during the vacuum tests). Indicators provide a visualization of the state of the vacuum system in manual and automatic mode. The second group of keys and an encoder handle are located on the right side of the panel and are designed to control the most important and frequently used functions of the leak detector (start/stop tests, object change, background compensation).The keys start / stop, as well as background compensation have a light indication of the state. In case of pressing the locked buttons, the acoustic radiator (situated on the print board under the control panel) makes a sound to report an error.

The design of the keyboard and the functions of control units is represented in Figure 16.

1- Start/Stop button (СТАРТ/СТОП)

2- Start/Stop button indicator

3- Zero button (НОЛЬ)

4- Zero button indicator

5- Menu button (МЕНЮ)

6- Two-position encoder handle

7- Manual mode indicator (РУЧНОЙ РЕЖИМ)

8- Leak indicator (ТЕЧЬ)

9- Object change button (СМЕНА ОБЪЕКТА)

10- Color graphic display

11- Valve Vent button and indicator (НАПУСК)

12- External leak valve button and indicator

13- Forepump N2 button and indicator

14- Valve V3button and indicator

15- Valve V2 button and indicator

16- Valve V5 button and indicator

17- Valve V4 button and indicator

18- Pump N1 (TMP) button and indicator

19- Cathodes state button and indicators

Figure 16 - The leak detector control panel design.

The functions of control and indication units:

MENU button - ![]() - provides the graphical interface displays changes. User settings interface is displayed by means of the MENU button and password input. Password is input with the encoder handle. A necessary character from the display list is chosen by rotating the handle; the handle pressing confirms the input of the selected character).

- provides the graphical interface displays changes. User settings interface is displayed by means of the MENU button and password input. Password is input with the encoder handle. A necessary character from the display list is chosen by rotating the handle; the handle pressing confirms the input of the selected character).

ZERO button - ![]() - provides the dependance between the current signal value and its background value (dynamic background compensation). ZERO button is active during the vacuum test cycle, only if the type of dynamic background compensation is used.

- provides the dependance between the current signal value and its background value (dynamic background compensation). ZERO button is active during the vacuum test cycle, only if the type of dynamic background compensation is used.

In the process of the automatic configuration / calibration, this button is locked.

START / STOP button - ![]() - starts or stops the vacuum tests cycle in the automatic mode, and interrupts the current cycle of the automatic ajustment / calibration without saving the results. In manual control mode, this button is locked.

- starts or stops the vacuum tests cycle in the automatic mode, and interrupts the current cycle of the automatic ajustment / calibration without saving the results. In manual control mode, this button is locked.

Button OBJECT CHANGE - ![]() - stops the the vacuum tests cycle and the atmosphere venting onto the leak detector inlet and the tested object. In manual mode, this button is locked.

- stops the the vacuum tests cycle and the atmosphere venting onto the leak detector inlet and the tested object. In manual mode, this button is locked.

The mimic panel control buttons:

Active only in manual control mode, except for the buttons S, V5 and V6.

Button V1- ![]() – controls the valve ‘OBJECT CHANGE’. State of the valve is indicated by green color next to the button. Active only in manual control mode.

– controls the valve ‘OBJECT CHANGE’. State of the valve is indicated by green color next to the button. Active only in manual control mode.

Button V6 - ![]() - connects the external leak during the leak detector calibration. State of the valve is indicated by green color next to the button. Active in manual and automatic control modes.

- connects the external leak during the leak detector calibration. State of the valve is indicated by green color next to the button. Active in manual and automatic control modes.

Button V5- ![]() - connects the built-in leak during the leak detector calibration. State of the valve is indicated by green color next to the button. Active in manual and automatic control modes.

- connects the built-in leak during the leak detector calibration. State of the valve is indicated by green color next to the button. Active in manual and automatic control modes.

Button V2- ![]() – controls the direct flow valve. State of the valve is indicated by green color. Active only in manual control mode.

– controls the direct flow valve. State of the valve is indicated by green color. Active only in manual control mode.

Button V3- ![]() – controls the pre-pumping valve and the counterflow mode. State of the valve is indicated by green color. Active only in manual control mode.

– controls the pre-pumping valve and the counterflow mode. State of the valve is indicated by green color. Active only in manual control mode.

Button V4- ![]() – controls the pumping valve of turbo-molecular pump. State of the valve is indicated by green color. Active only in manual control mode.

– controls the pumping valve of turbo-molecular pump. State of the valve is indicated by green color. Active only in manual control mode.

Button N1 - ![]() – controls the turbo-molecular pump. Its state is indicated by dichromatic indicator. In normal mode (the pump functions properly and operates at work frequency of rotation) the green indicator lights up; if some fault happens, the red indicator lights up.

– controls the turbo-molecular pump. Its state is indicated by dichromatic indicator. In normal mode (the pump functions properly and operates at work frequency of rotation) the green indicator lights up; if some fault happens, the red indicator lights up.

Button N2- ![]() - provides a synchronous control of forepump and its vent valve V7. The pump ON state corresponds to the closed valve state, the green indicator lights up.

- provides a synchronous control of forepump and its vent valve V7. The pump ON state corresponds to the closed valve state, the green indicator lights up.

Button S ![]() – controls the analyzer cathodes. In the standby mode the successive pressings of this button enable and disable the active cathode (in kilter of both cathodes it is a cathode 1, if the cathode 1 is off kilter, the cathode 2 will be active). During the vacuum tests in automatic mode, this button is locked. In manual mode the operator can switch the cathodes or shut-down both of them by their successive pressing. In order to improve the usability, the mode of cathodes cyclic switching by the button S pressing is deactivated when the currently working cathode remains switched on for more than 30 seconds. The ON state of kilter cathode is indicated by green color. If a fault happens, the indicator lights up in red.

– controls the analyzer cathodes. In the standby mode the successive pressings of this button enable and disable the active cathode (in kilter of both cathodes it is a cathode 1, if the cathode 1 is off kilter, the cathode 2 will be active). During the vacuum tests in automatic mode, this button is locked. In manual mode the operator can switch the cathodes or shut-down both of them by their successive pressing. In order to improve the usability, the mode of cathodes cyclic switching by the button S pressing is deactivated when the currently working cathode remains switched on for more than 30 seconds. The ON state of kilter cathode is indicated by green color. If a fault happens, the indicator lights up in red.

The indicators LEAK are designed for visual indication of the fixed spoilage threshold being exceded by the current signal level, that considerably facilitates the operator’s work during the stream-handling product verification in industrial conditions. The flashing red light corresponds to a signal exceeding the spoilage threshold, the green indicator light - the signal is below the threshold.

The MANUAL MODE indicator is red when the manual mode is switched on and is designed to increase the operator's attention at work in this potentially unsafe mode.

3.4 Software

The software is installed by the manufacturer and may be upgraded. The version number of installed software is displayed after the leak detector power is switched on.

The Central Board controls a number of peripherals (modules) on the internal bus RS485, providing a high leak detector maintainability in case of some modules fault. These peripheral modules are:

- valve control unit that provides the power supply of valves requiring the power chain forcing at the moment of opening;

- analyzer power unit that provides the normalization of the necessary electrical signals for the mass spectrometer ions source;

- the engine and valves control board that provides the control of valves DN 1.6 (do not require the electric forcing), of the opto-relays of switching on the forepump and of turbo-molecular pump controller;

- the pressure passage amplifiers supporting the pressure sensors P1 and P3 electrical mode, as well as their signals processing ;

- electrometric amplifier, which provides pre-processing of the signal emitted on the ion collector of the mass-spectrometer cell.

The control system allows to set an automatic or manual testing mode and provides the parameters settings necessary for correct operation. Leak detector settings that influence the control system efficiency, as well as the transition to the manual control mode are protected with a password.

The default password is: AAA.

To prevent unauthorized access to leak detector password-protected settings, it is recommended to change the password to the unique symbols combination. The information about the new password must be entered in the device logbook and be available only to the competent service staff.

3.5 Control of settings

Check the position POWER of the switch. It should be in position ‘0’. Connect the cord to the block on the back of the leak detector. Connect the plug to the socket of 220 V, 50 Hz, equipped with a protective grounding contact.

The leak detector switching on

Set the switch POWER on the power block to ‘I’ position.

At the power supply beginning, the control panel display should start working and display the loading window, with the name of the device, the name of the manufacturer and the version number of installed software. At the leak detector start all the elements of the vacuum system are tested. Depending on settings, the cycle of automatic configuration / calibration by built-in leak can also be launched. At the end of switching on, the ready mode ensues; it is indicated by the message ‘Ready mode’ in the status bar at the bottom of the display. During the leak detector start-up and testing its settings can be displayed, so it can be controlled in the manual mode. This opportunity can be used for troubleshooting if the device can’t be brought to ready mode by the automatic control system because of a fault.

3.5.1 Settings menu

The settings menu is used for leak detector parameters settings which determine its functioning in all modes and also contains the settings which need not fast changes, i.e. not required during the current cycle of vacuum tests. Depending on the test scheme, parameters of the tested objects, the vacuum tests technological instructions requirements of and others factors, the optimal settings values may vary.

For displaying the settings menu, press the MENU button, then input the correct password. MENU button is unavailable in automatic mode during the vacuum tests conduction as well as during the process of the leak detector automatic configuration / calibration.

The password input display is shown in Figure 17.

Figure 17 - The password input display

Password input procedure:

Press the MENU button. In the right side of the screen, the letter set displays. To choose a character, rotate the encoder handle, highlight the appropriate character and confirm the choice by pressing the handle (ENTER function). Repeat these procedure for all password characters (default password is ‘AAA’). Then set the marker on PASSWORD INPUT field and press ENTER. If the correct password is entered, the screen will display a list of leak detector settings. If the password is incorrect, the message ‘Invalid Password’ will be displayed; the control system will be in a state of the password re-entering. If the password is entered incorrectly three times, an automatic exit from this menu will follow.

To navigate through the menu settings (Figure 18), rotate the encoder handle. The selected menu item is highlighted, and after a short delay, the name of the item will be replaced by the current set value of the corresponding parameter. This feature allows the value of established parameters to be viewed without entering the corresponding menu items. The changing of the current (highlighted) parameter is realized by pressing encoder handle (ENTER). The set value changing is realized by rotating the encoder handle: clockwise - increases the value, anticlockwise – decreases the value. The set value is saved in the memory after pressing the button ENTER.

Figure 18 - Leak detector settings menu

The settings menu has the following parameters:

Manual\auto leak detection - the choice of leak detector mode: automatic or manual control.

Calibration after start - enables or disables the leak detector automatic adjustment/calibration at power switched on.

Switch on counterflow threshold - allows to set the pressure at the leak detector inlet (P3), so that the control system switches the leak detector in the mode of counter flow (at the automatic control mode) or disables the leak detector to switch to counter flow mode at any pressure values at the inlet when the parameter is set to a value ‘no switching to the counterflow.’ The possible range is 5-1000 Pa.

Switch on direct flow threshold - allows to set the pressure at the leak detector inlet (P3), so that the control system switches the leak detector in the mode of direct flow (at the automatic control mode) or disables the leak detector to switch to direct flow mode at any pressure values at the inlet when the parameter is set to a value ‘no switching to the counter flow.’ The possible range is 0,5-20 Pa.

Note: In order to ensure the stability of the leak detector pumping system work, it is not recommended to set the value of switching to the direct flow threshold more than 10 Pa at work with objects of more than 5 liters volume without use of auxiliary pumping equipment.

Measurement Units - measurement setting for displaying the flow and pressure values. It is possible to set the following dimensions: ‘m3. Pa/s – Pa’, ‘micronHg.l/s – mm Hg’, ‘mbar.l/s – mbar’, ‘atm sm3 /s – atm’, ‘mV EA – Pa’. The value of the signal flow in mV EA (millivolts of output voltage of the electrometer amplifier) allows to make the manual calculations of the flow values for solving non-standard test problems.

Maximum time of pump - the setting of the maximum allowed time for the leak detector to be in the pre-pumping mode up to a pressure value making it to switch to the direct flow mode or counter flow mode. Do not set the long duration of the pre-pumping, because the forepump continuous work at a high inlet pressure can lead to increased oil outflow with the flow of pumped gas. The possible range is 1-99 min.

Time of signal integrator - determines the degree of the electrometric amplifier outlet signal smoothing. The increase of this parameter makes it easier to identify the signal on the background of noise and raise the sensitivity level in some cases. The decrease of this parameter reduces the leak detector reaction time, but increases the noise. The possible range is 300-9000 ms.

The cathode in ready mode - specifies the cathode mode (on/off) when the leak detector is in ready mode. The operator can enable or disable the cathode manually in ready mode by pressing the S button. The continious cathode ON state in the ready mode maintenance reduces its lifetime, but accelerates the signal stabilization at transition to the vacuum tests mode, because due to gas emanation during the cathode heating a considerable change of outlet signal level occurs.

STD internal leak value - sets the value of internal leak, installed in the leak detector. The internal leak set value must coincide with the data specified in the certificate of leakage verification. As a rule, this value is indicated on the leak body. At an internal leak value entering the measure units installed in the leak detector settings must coincide with those indicated in the leak certificate.

Calibration temperature - the temperature setting in Celsius degrees, at which the internal flow was verified. This value is indicated in the leak certificate.

Total work time - the parameter indicating the total leak detector operating time. Changing it is impossible. At delivery, the leak detector already has an operating time of a few tens of hours, due to its configuration and its technological running-in by the manufacturer.

Time of leak stabilization - sets the waiting time of the background signal stabilization and of the signal from the external control leak during the automatic calibration by the external leak. This time can vary widely depending on the characteristics of the tested object to which the external leak is connected during the calibration process. The possible values range is 1-400 min. Before the calibration on external leak, it is recommended to determine this parameter for the tested object, by measuring the time when a steady signal is registered after the external control leak (installed at the object) opening. A correct identification and setting of the constant background stabilization time in the leak detector allows to achieve a maximum calibration accuracy by the external leak and to avoid an extra duration of the calibration process due to excessive waiting time of the signal level stabilization.

Control - the leak detector control mode selection: local (from the front panel) or external (from the remote PC or external control system). The work in an external control mode allows to connect the leak detector to the systems of data storage and processing and integrate the device into the automated lines.

The password exchange - after the encoder pressing, the display for entering the new password appears.

The new password input process is similar to this of a password input used for the settings menu displayng.

After entering the new letter password, and after pressing ‘password exchange’, you need to re-type the new password and press ‘confirm password’.

The repeated input of new password makes the incorrect password setting impossible.

Time/Date - calendar and clock setting. Year, month, date, hours, minutes, seconds are selected successively. The current date and time are used at saving and further browsing of measurements results. They don’t influence the information of the device operating time.

3.5.2 Default settings

For acquaintance with the methods of leak detector settings modes, and for specification of the set parameters values, the settings check is carried out.

To check the settings, press ‘MENU’ button, enter the password (the default password is ‘AAA’), consecutively select and input the characters by the encoder handle rotation and confirm the choice by pressing the handle (ENTER function). Then choose the option ‘Enter Password’ and press ENTER. If the password is not correct, there will be a sound signal and the message bar will display ’password is incorrect’, then you can re-enter the password.

On the settings entry display, check the values of default settings in the range specified in the Table 5, select consecutively the appropriate menu items by rotating the handle; in 1-2 seconds, instead of the item name the current value will be shown. If it is necessary to change the default settings, select a required menu item and press ENTER, then change the set values by rotating the handle; to confirm the setting changes, press ENTER.

Table 5

|

Item |

Value range |

Default setting |

Note |

|

Calibration after start |

On/Off |

Off |

|

|

Transition to the counter flow threshold |

0,1-1000 Pa/ Counter flow is prohibited |

500 Pa |

|

|

Transition to the direct flow threshold |

0,1-20 Pa/ Direct flow is prohibited |

5 Pa |

|

|

Measurement unit |

m3.Pa/s (Pa); mm.hg..l/s(mm Hg);

|

m3. Pa/s (Pa) |

|

|

Maximum pumping time |

1-99 min |

10 min |

|

|

Signal integration time |

300-9000 ms |

1500 ms |

|

|

Cathode in ready mode |

On/Off |

On |

|

|

Internal leak value |

1.10-7 -9,9.10-9 m3. Pa/s |

Complies with the value specified in the internal control leak certificate |

|

|

The verification temperature, ºС |

15-35 ºС |

Complies with the value specified in the internal control leak certificate |

|

|

Operating time |

Complies with the current operating time resulted from the technological running-in by the manufacturer |

- |

|

|

The time of background signal stabilization |

1-400 min |

1 min |

|

|

Control |

Local/External |

Local |

|

|

Password exchange |

from 1 to 14 characters |

AAA |

It is recommended to change a password at the first usage |

|

Time/Date |

- |

Current time |

Install a local time |

To leave the settings entry display, press ‘MENU’ button (for return to either automatic or manual mode), or select the menu item ‘Manual / Automatic mode’. Select the desired mode by rotating the encoder handle and press ‘ENTER’.

3.6 Operating modes

The control system provides the leak detector operation in two modes: automatic and manual ones. To carry on everyday activities, it is recommended to use the automatic mode. The manual mode is used mainly for non-standard work, as well as for repair and adjustment, so it should be practiced with caution and only by qualified personnel.

3.6.1 Automatic mode

The is the basic operation mode. The leak detector control system passes to the default automatic mode just after the power is turned on. This is a safe mode because an operator can’t make any damage to leak detector by wrong actions. The control system monitors the state of all elements and blocks any unsafe actions. The automatic control mode maintains the following main phases:

The leak detector work start.

After switching on the toggle POWER SUPPLY situated on the leak detector back panel, the loading window is displayed. It shows the type of device, the manufacturer name, and the software version. Then the automatic launch of the vacuum system elements is initialized, resulted by the leak detector readiness for the vacuum tests. If the leak detector settings provide a passage to the automatic configuration/calibration after switching-on, the process of automatic configuration/calibration by the internal leak is carried out additionally (regardless of the external leak connection to the appropriate junction). During the leak detector start-up and testing, it can be switched to a manual control mode by pressing ‘MENU’ button. It can be used for troubleshooting if the automatic control system cannot ensure the transition to the ready mode because of some malfunction.

Ready state.

State from which the process of automatic vacuum tests can be started. In this state: N1 is accelerated to the normal speed, N2 is ON, V4 is opened. The current cathode can be switched off or on, depending on the leak detector settings. The operator can also enable or disable the current cathode by pressing S button. If long operation downtimes occur it is recommended to disable the cathode, in order to preserve its lifetime length. The automatic control mode is displayed. The leak detector can stay in this state for unlimited time, waiting for operator’s further actions.

Wait state.

An automatic control system puts leak detector in this state after an error, non-critical for its operability occurs. However, the error may influence its normal performance (e.g. in case of the automatic configuration / calibration process failure). The leak detector state is identical to this of readiness, but START / STOP button is locked, so the vacuum tests cycle cannot be launched before debugging. The status bar displays an error message. The leak detector can stay in this state for unlimited time, waiting for trouble-shooting.

Stop state.

An automatic control system puts the leak detector in this state after an error, critical for its operability occurs. In this state, all the vacuum system elements are disabled. The status bar displays an error message. Only MENU button is available. It provides an access to the leak detector settings or to the manual mode, for trouble-shooting.

Object changing.

This mode is designed to vent the atmosphere to the leak detector inlet in order to change the tested object. Operator activates it from the Ready state, or from vacuum tests, or from Wait state, by pressing CHANGE THE OBJECT button. If this button is pressed at the vacuum tests mode, the test mode will be interrupted. The vent valve is opened until P3 value equal to the atmospheric pressure is reached, then V1 is automatically closed and the leak detector will be switched to the Ready state.

Automatic adjustement / calibration by the internal leak.

The mode is designed for automatic adjustment/calibration of the leak detector mass-spectrometer to the registration of the tracer gas (helium) by changing the accelerating voltage within the small limits. As a result, the new value of the accelerating voltage providing the maximum signal value from the internal helium leak, is recorded in the leak detector memory. Simultaneously, the measuring scale calibration takes place, which allows the value of the specified signal to be compared with the flow measurement units fixed in the settings. It is recommended to carry out from time to time the automatic adjustment / calibration during operation (especially when the external conditions – temperature, humidity, etc. vary). Thus the analyzer setting correctness, therefore, a maximum device sensitivity are provided. To interrupt the current cycle of the automatic calibration, cancel its results and put the leak detector in the Ready mode, press START / STOP button. Depending on the leak detector settings, this mode can be started up automatically during the first switching on, regardless of whether the external leak valve is connected to the circuit. When the automatic adjustment / calibration is finished, the reached value of the minimal detectable flow by the internal leak is recorded in the leak detector memory, and the device switches to the Ready mode.

The minimal detectable flow check.

The check is realized from the leak detector automatic control screen.

Start the adjustment / calibration by the internal leak by selecting ‘Calibration Manual / Auto’ and press ‘ENTER’, then select ‘internal autotuning’ by rotating the encoder and start the process by pressing ‘ENTER’. During the autotuning, the analyzer output signal curve is displayed, having the typical shape of inverted parabola (symmetric, as in Fig. 19, or asymmetric), with a prominent maximum. If there is no prominent maximum, restart the automatic adjustment / calibration by the internal leak. The specified form of the curve indicates the correctness of autotuning and the analyzer operability. After the adjustment / calibration is finished, the value of the minimal detectable flow with the fixed dimensions should be displayed. The minimal detectable flow should not exceed the passport value. If the minimal detectable flux exceeds this value, it is necessary to carry out the adjustement of the analyzer magnetic system.

Note. The value of the minimal detectable flow in the counter flow mode during the process is constructively related to the value of the minimal detectable flow in the direct flow mode through the correction coefficient (set by the manufacturer) and is not checked separately.

Figure 19 – Analyzer autotuning to the helium peak

The automatic calibration by the external leak.

This mode is similar to this by the internal leak, however, there is no analyzer autotuning to the helium peak. It can be started in the ‘probe’ mode, or a in the universal mode if an assembled external leak (available on request) is electrically connected to the joint ‘EXT. FLOW’ on the leak detector back panel. The main calibration by the external leak purpose is: to increase the accuracy of leaks estimates in the real tested objects (especially those of large volumes or having an extra gas loading). The external factors, varying widely, can in certain cases considerably distort the accuracy of leak detector indications if it is calibrated by the internal control leak only. It is necessary to take into account that, to achieve the most exact correspondence of leak examination results to the real flow value, it is necessary to carry on the leak detector calibration by the external leak. The detected leak location and the operating mode during the calibration by the reference leak, as well as the further examined leak observation, should be as identical as possible. For example, the use of leak detector calibration results by external leak in the counter flow mode is absolutely inapplicable for estimates of leaks values in the direct flow mode. It is recommended that the operator, during the calibration by the external leak, determines consecutively a minimal detectable flow for both modes (counter flow and direct flow ones). Later, during the automatic vacuum tests, the modes in which the calibration is not successful, or not done will be blocked.

Manual calibration by external leak.

At the lack of a controlled external leak, a manual calibration by external leak can be done. This calibration is similar, with the exception that the external leak is opened and closed manually; the moment when it is necessary to open or to close a helium leak is displayed in the message bar.

The calibration of mode with accumulation.

The obligatory conditions for selection of the mode with accumulation are the external controlled leak and operation in direct flow. The leak detector will automatically control the external leak by accumulating first the background (in a given accumulation interval), then the helium flow of standard leak (for the same time interval), with a calculation of the minimal sensitivity after the accumulation and of the sharpness of the signal growth.

The calibration of mode with the probe.

This calibration is possible after the leak detector is switched to PROBE mode. This action doesn’t depend on the external leak item connection/disconnection to the leak detector, because the probe calibration is carried out by the external control capillary leak. In this case, during the calibration, the leak detector control system sends to the operator requests to supply or to stop the tracer gas from the leak to the probe (the process is similar to the manual calibration by external leak).

Vacuum tests with dial switching of the leak detector vacuum system.

This mode is started with button START/STOP from the automatic mode screen. The repeated button pressing stops the mode and switches the leak detector to ready state. The mode can be also interrupted with button OBJECT CHANGE or automatically, by the leak detector control system in case of some faults. In automatic mode of vacuum tests all interlocks, designed in leak detector, are active. This mode can be realized in three variants – with or without accumulation, and probe (their description is given further).

Automatic mode of vacuum testing without accumulation includes 3 phases (states of leak detector):

- pre-pumping of the tested object. The mode is used for pressure reduction at the leak detector inlet up to the counterflow threshold (or the direct flow at once, if operation in counter flow mode is prohibited by leak detector settings or by negative results of the previous calibration by external leak, or the inlet pressure allows to switch the leak detector to the direct flow mode). In this mode, the analyzer cathode is turned on (if it is previously turned off), analyzer is pumped by pump N1, valve V4 is closed, V3 is opened. The system provides pumping off the leak detector inlet, with a vacuum testing object connected to it, up to a pressure when leak detector switches to the counter flow (or direct flow) mode. For maintaining a sufficient vacuum value at the turbo-molecular pump outlet in the process of long-term pumping off of the external object, the system provides periodical closing of V3 and opening of V4. The total time of pre-pumping before pressure P3 reaches the counterflow threshold (or direct flow) should not exceed maximum duration of pumping-off, set in leak detector settings. The minimum duration of staying in pre-pumping mode is 10 s;

- counter flow mode. In this mode, the countercurrent flow scheme of vacuum tests signal value is registered. The analyzer is pumped off by pump N1through the valve V4. The valve V3 is open, providing leak detector inlet pumping off, as well as that of pump N1 by means of pump N2. The transition to this mode (if it is not prohibited by the leak detector settings, or by negative results of preceding calibration by external leak in the counterflow mode) from the pre-pumping mode is carried out when the pressure P3 reaches the counterflow threshold. If the maximum value of the flow measurement scale is exceeded by more than 5 s, an automatic turn off of the vacuum test mode occurs, the status bar displays ‘helium poisoning’. The counter flow mode allows to work with higher gas pressures at the leak detector inlet in comparison with the direct flow mode. The counter flow mode is used for detection of leaks with a great helium concentration in of leak sites, for leaks localization by blowing method or probe method.

- direct flow mode. The most sensitive mode. V2 and V4 are open, V3 is closed. The analyzer is connected directly to the leak detector inlet. Switching to this mode is realized during vacuum tests from the counter flow or pre-pumping modes when pressure P3 reaches the switch on direct flow threshold, if the transition to this mode is not prohibited by the leak detector settings, or by negative results of previous calibration by external leak in the direct flow mode. If the maximum value of the flow measurement scale is exceeded by more than 5 s, an automatic transition to the counter flow mode occurs. The direct flow mode is realized through the valve V2. This mode is most widely used for determination of the leakage value of the object by method of vacuum chamber, accumulation, as well as by method of blowing. The direct flow mode is more sensitive in comparison with the counter flow mode and allows to find lower helium concentrations in the tested volume.

Automatic mode of vacuum tests with accumulation is designed for measuring small helium flows, with an increased sensitivity in the direct flow. In this mode, first the background flow, then the helium flow accumulation is carried out by means of timer, during the corresponding time intervals set in the leak detector settings.

This mode includes 3 phases (states of leak detector):

- pre-pumping of a vacuum tested object. This mode is designed to reduce the pressure at the leak detector inlet, up to the switch on direct flow threshold. In this mode, the analyzer cathode switches on (if it was previously turned off), the analyzer is pumped off with the pump N1, the valve V4 is closed, the valve V3 is open; the pumping of the leak detector inlet with a vacuum testing object connected to it, up to a pressure when leak detector switches to the direct flow mode.

For maintaining a sufficient vacuum value at the turbo-molecular pump outlet in the process of long-term pumping off of the external object, the periodic closing of V3 and the opening of V4 is done. The total time of pre-pumping before pressure P3 reaches the directflow threshold should not exceed maximum duration of pumping-off, set in leak detector settings. The minimum duration of staying in pre-pumping mode is 10 s;

- direct flow mode, ‘the background accumulation’. V2 and V4 are open, V3 is closed. The analyzer is directly connected to the leak detector inlet.

Switching to this mode is realized during vacuum tests from the pre-pumping mode when pressure P3 reaches the switch on direct flow threshold, and if the transition to this mode is not prohibited by negative results of previous calibration by external leak in the direct flow mode. The direct flow mode is realized through the valve V2. The external object, in this case, is usually the vacuum chamber. Direct flow mode is realized through the valve V2. After background is stabilized, the command ‘Start accumulation’ – ‘Background accumulation’ starts the background accumulation in the chamber. Valve V4 closes and, if there is control, the external chamber pumping turns off. The background accumulation is completed after a time interval defined in the leak detector parameters as ‘accumulation time’. The valve V4 and the external pumping open.

- direct flow mode, ‘the helium accumulation’. The tested object is exposed to the helium influence by means of blowing or another way; the accumulation start is activated by pressing ‘ENTER’ on the item ‘Helium accumulation’ (this item appears automatically instead of ‘background accumulation’). The valve V4 closes, and the external pumping is stopped. The helium accumulation is realized and it is completed after a time interval defined in the leak detector parameters as ‘accumulation time’. The valve V4 and the pumping open, the value of the accumulated helium flow is calculated. This value displays until the accumulation process repeats. The accumulation can be done many times during one test cycle.

Automatic testing mode by probe method includes 2 phases (states of the leak detector):

- inlet pre-pumping. This mode is designed for reduction of pressure at the leak detector inlet up to pressure, needed for valve V4 opening. The time of pre-pumping before pressure P3 reaches the counterflow threshold should not exceed maximum duration of pumping-off, set in leak detector settings. The minimum duration of staying in pre-pumping mode is 10 s;

- counter flow mode. In this mode, the counter flow scheme of vacuum tests signal value is registered as in the mode without accumulation, however, there is a difference: during operation in the probe mode, the control of flow is carried out with the probe by measuring of pressure Р3. In case of Р3 pressure decrease below the half of certificate value (for standard versions of leak detectors TI1-50 this value is 30 Pa), the probe is considered to be clogged. The status bar displays ‘probe clogged’, the current testing cycle is interrupted, and leak detector switches to the ready mode, which allows to restart the cycle after probe replacement, without any other additional actions.

Attention: before the tests in the probe mode start, the caps should be removed from the probe.

3.6.2 Operator's work screen in the automatic control mode

The operator's work screen is designed for everyday carrying out similar vacuum tests. When the leak detector is switched on, the control program provides automatic transition to the screen. The menu contains the most important information about leak detector operation (Figure 20).

Figure 20- Operator's work screen in the automatic control mode

- diagram of leakage flow value in units specified by operator. Fragments of the curve, located above the level of the specified rejection threshold are displayed in red;

- numerical expression of leakage flow value, synchronously repeating the value, presented in graph;

- numerical expression of flow average value for all time period shown in the diagram, Qav (only for software version 1.4 and higher);

- numerical values of pressure in leak detector vacuum system (Р1, Р3);

- status bar. This bar displays information about current operation mode, as well as error messages;